Saw stand

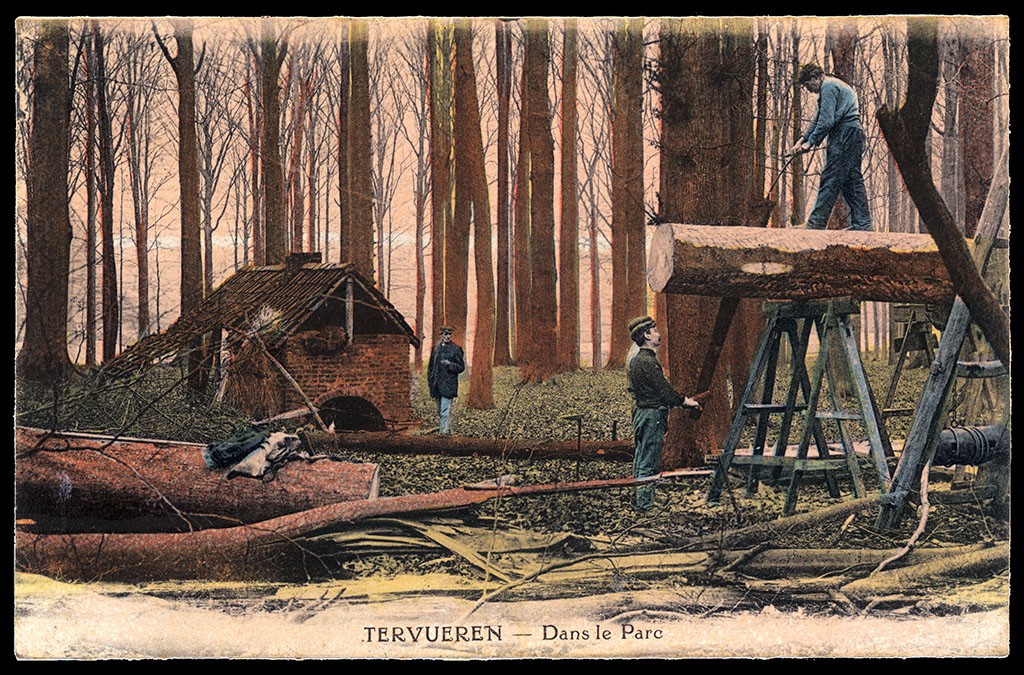

With the frame saw and the crane saw you can saw logs into planks. To be able to work with two people on these large saws, the log to be sawn must be placed at a height, on a saw stand.

There are different types of saw stands, depending on the location and use. Work is often done above a pit. The trunk can then easily be rolled above the hole. If work is carried out on trestles or a fixed scaffolding, the log must be lifted with a hoist. In the stand here, the trunk can be pushed up along the sloping beam.

Saw pit - © Musée de la Vie Wallonne

Rip sawing

When sawing planks, you cut lengthwise in the direction of the wood grain. The shape of the teeth and the way they are sharpened make this possible. The crane and frame saw only cut during the downward movement. In particular, the sawyer standing above guides the saw along the chalk lines. On this saw stand the beam is turned halfway down the sawing process to be able to saw the second half.

© Martin Corlazolli

© Martin Corlazolli

Frame saw and crane saw

Since ancient times, planks have been sawn with a saw blade that is clamped in a wooden frame: the frame saw. At the end of the 18th century, sturdier saw blades were made and the crane saw appeared. The crane saw was used in Belgium until the interbellum period. In large parts of the world, sawing with a crane saw is still a daily occurrence.

Saw stand with frame saw. Miniature from Conquestes et croniques de Charlemaine, volume III by Aubert David, 1458 (© Brussels, Royal Library)

Saw stand with crane saw in the Sonian Forest © Koninklijke Heemkundige Kring Sint-Hubertus Tervuren