How to build wooden scaffolding

The MOT's experimental built

This scaffolding project is part of our research into historical building techniques and building professions. The stonemason is only one aspect, also blacksmiths, carpenters, roofers, brick makers and so on play a very important role in historical constructing.

Our plan is to turn the facade and courtyard of the Prinsenkasteel ruin into a castle under construction, instead of a castle in disrepair. The making of the wooden scaffolding is only the first step in our large-scale construction/stone project. Other installations such as hoists and construction lodges will further complete this historic construction site.

The scaffolding complements our latest exhibition Scaffolding and stone in the keep, a project also realized with the financial support of the Province of Flemish Brabant.

The real deal

Scaffolding has always been important for erecting tall structures. An imposing building like the Prinsenkasteel, with walls of up to 20 meters high, undoubtedly involved a lot of scaffolding. How did they manage that at the time?

A question that caught our imagination in such a way that we set to work on it ourselves. Together with Scouts en Gidsen Grimbergen we took on the challenge of building a wooden scaffolding ourselves in the traditional way, with round wood and rope. The result is shown below in a timelapse.

Research

This historical reconstruction of the wooden scaffolding at the Prinsenkasteel could only be built after an examination of the literature and iconography in our museum library. It is not just an eye-catcher for the exhibition Scaffolding and stone.

With this project we want to collect knowledge about the important technique of building scaffolding, by gaining experience in building itself and making this knowledge and experience known to a wide audience, both on site and online.

That's how they used to do it

As soon as people started to build something that was higher than shoulder height, there was a need for a platform to stand up during work and to place the building materials on. The larger and higher the works, the more complex those raised constructions are, from a shelf on two boxes to scaffolding with several floors. To make the scaffolding accessible you had ladders and sometimes sloping surfaces. There were also necessary hoists to lift the building materials.

Scaffolding, like all techniques, has undergone an enormous evolution. Until about 1950 there was one constant in this region: the frame of a scaffolding was built from (round) wood. Since then, metal has largely replaced wood for the vertical elements, but wooden horizontals are still used in many scaffolds.

Scaffoldings are by definition temporary structures to be taken down. Once the construction is completed, they are dismantled and the scaffolding materials are recovered as much as possible to be reused. That is why the parts of wooden scaffolding were largely connected with rope. Nails are more difficult to remove and will damage the wood. The rope could be used several times and was therefore more durable and cheaper than nails. In the first half of the 20th century, people started to experiment with metal connecting pieces, steel wire and chains in order to connect the wooden scaffolding parts more quickly and easily.

Scaffolding components

Each scaffold consists of vertical scaffolding standards, connected with horizontal ledgers. To make the construction rigid, diagonal braces are attached to it. This creates solid triangles that cannot be deformed.

At right angles to this framework there are transoms that carry the platforms. In more recent times these consisted of planks, but in many medieval images we see woven panels. Such woven boards, called hurdles, have many advantages. Sawing planks was expensive, very labor-intensive by hand and sawmills were certainly not available everywhere. The raw material for hurdles, flexible straight branches from coppices are much cheaper than straight trunks for cutting planks. Hurdles are both strong and light. Yet scaffolding planks were also used on medieval construction sites.

Different types of scaffolding

Which type was used depends on the nature of the works (new construction, renovation, large masonry, small masonry) but also on the place and time.

Scaffolding can stand completely free from the structure, with two rows of vertical posts. But usually they are attached to the structure that was being erected. To this end, putlog holes were made in the wall during construction in which the putlogs can rest. This way of scaffolding not only allowed you to save an enormous amount of wood, it offered more stability and security. Not all scaffolding support on the ground, they can also rest solely on the structure itself, and systematically move upwards with the construction.

Putlog holes were usually filled to prevent water from entering. But in some buildings they were left visibly open in the facade. Sometimes they are reused during restoration works.

Supported by the Province of Flemish Brabant

© Österreichische Nationalbibliothek

In Asia, most scaffolding is still built in bamboo, as here in Nepal during the reconstruction after the severe earthquakes of 2015.

Call to action!

We are always looking for people who can provide us with information about wooden scaffolding, such as photos, testimonials... Have you worked or built such a scaffolding yourself? Do you have any useful facts or tips? Or can you supplement our collection with objects or documentation on the subject? Don't hesitate to contact us!

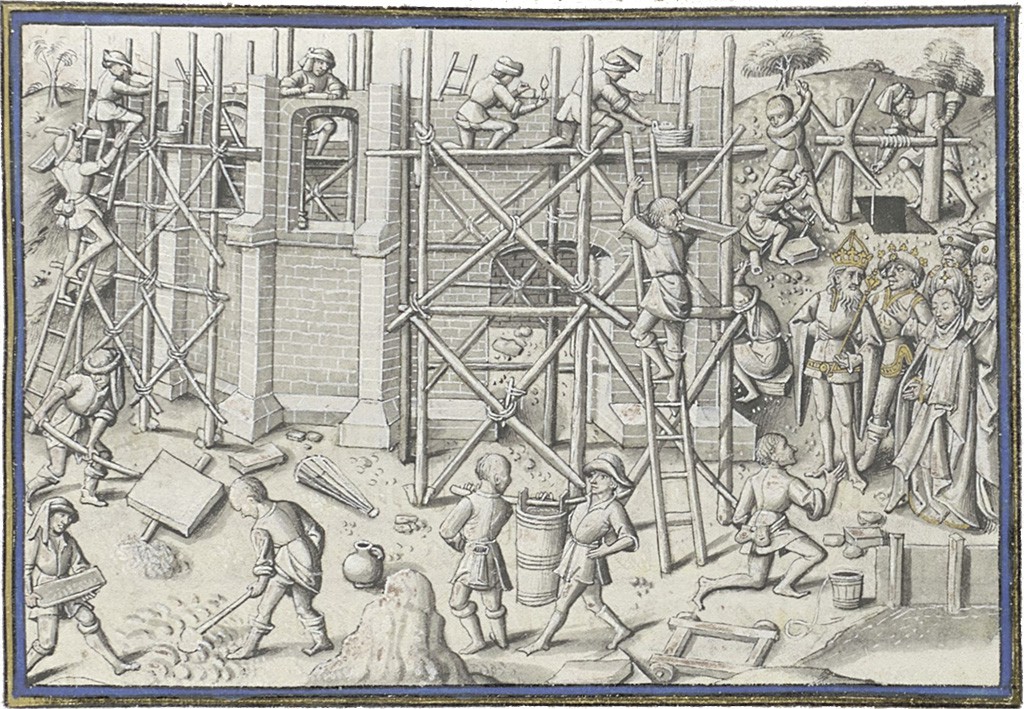

Building an abbey. Miniature from Conquestes et croniques de Charlemaine, volume III by Aubert David, 1458 (© Brussels, Royal Library)

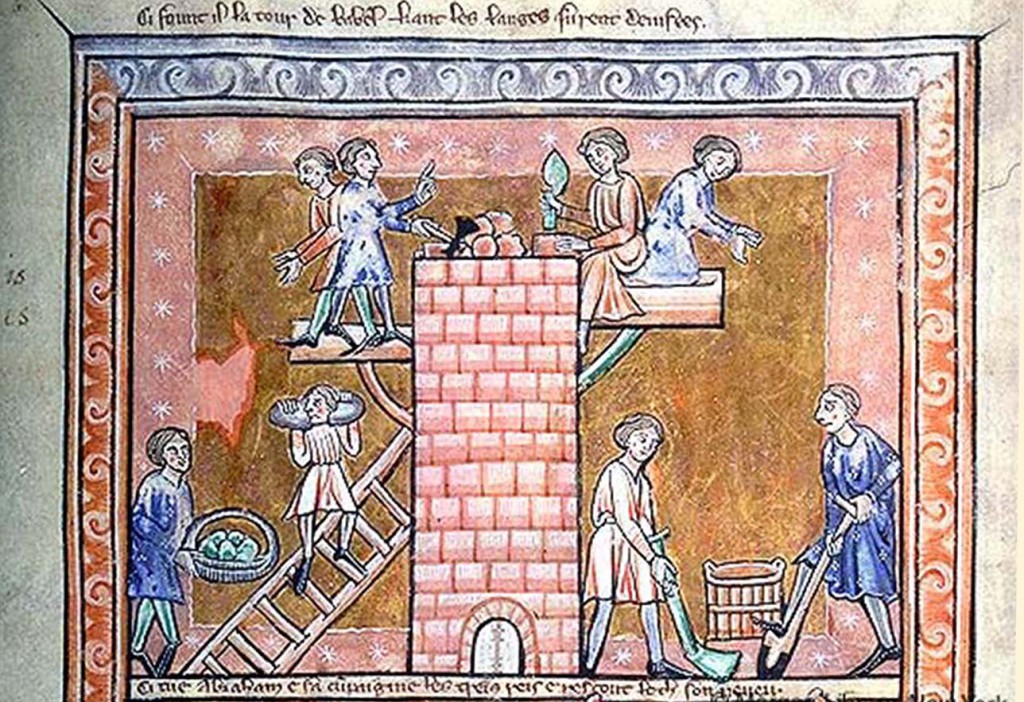

Miniature from the Huntingfield Psalter, ca. 1180 (© Morgan Library, New York)

Scale model in the MOT collection

This model, from the Provincial Safety Institute of Antwerp, was made around 1942 to show construction workers and contractors how to safely build and furnish a wooden scaffolding.

Model of a construction site ca. 1942